Resources

Environmental Resources

As an environmental services company, Elk takes pride in its knowledge of waste management, particularly hazardous materials. From waste transportation and disposal to emergency response, we have you covered. Below are some resources to provide quick answers. If you have any questions, please contact us!

New EPA e-Manifest Rule Impacts Large and Small Generators

The Environmental Protection Agency’s (EPA) final third e-Manifest rule amends certain aspects of the hazardous waste manifest regulations under the Resource Conservation and Recovery Act (RCRA), specifically about the e-Manifest system. As your environmental services partner, Elk Environmental Services is here to help you understand these changes.

Key Changes to the e-Manifest System:

- Registration Requirement: By January 22, 2025, all Large Quantity Generators (LQGs) and Small Quantity Generators (SQGs) must register and maintain an account with the EPA’s e-Manifest system.

- No More Mailed Copies: After this date, disposal facilities will no longer be required to mail final hazardous waste manifest copies to generators. Instead, the final signed manifests will be available for download directly through the EPA’s e-Manifest system.

- Access to Final Manifests: The new system ensures that all hazardous waste generators can easily access and receive final signed copies of their hazardous waste manifests online.

Action Required:

If your facility is a Large or Small Quantity Generator, it is essential to complete the registration process by the January 22, 2025 deadline. Failure to register may result in difficulties accessing your final manifests and staying in compliance with the regulations.

Resources from the EPA:

The EPA has provided several resources to help you understand the new requirements and register for the e-Manifest system:

- e-Manifest Final Rule Summary

- Instructions for e-Manifest User Registration

- Training Video on the e-Manifest Registration Process

Please Note: Very Small Quantity Generators (VSQGs) are not required to register since they are not mandated to use a Uniform Hazardous Waste Manifest. However, if your facility is a VSQG and you would like to receive final signed manifests for hazardous waste shipments, you may voluntarily register with the EPA. At ELK, we use Uniform Hazardous Waste Manifests for all shipments of Hazardous Waste that is subject to and managed in accordance with 40 CFR part 262, including those from VSQGs, so registration may be beneficial for obtaining copies of your final manifests.

Please feel free to contact us if you have any additional questions, and/or to discuss how this rule amendment will directly affect your facility.

A Guide to Handling Damaged Lithium Cells and Batteries for Waste Generators

Lithium cells and batteries are found in almost every industry, from agriculture to manufacturing. As indispensable power sources, they are found in a variety of electronics and equipment. Yet, with their benefits come responsibilities—proper disposal and management are crucial to prevent environmental hazards and ensure safety. For waste generators, packing and shipping damaged lithium batteries can be challenging.

Understanding Lithium Battery Waste

Universal vs. Hazardous Waste

EPA has determined that most lithium batteries on the market today are likely to be hazardous waste at end of life due to the reactivity (D003) and possibly ignitability (D001) characteristics. Undamaged lithium batteries can be handled under the streamlined management standards for universal waste. However, damaged batteries are more prone to short-circuiting, overheating, and potentially causing fires or thermal runaway. As a result, damaged lithium cells and batteries must be managed as hazardous waste and must be packaged for transport according to specific Department of Transportation (DOT) requirements. Environmental services companies are recommended to pack and ship damaged lithium cells and batteries to a recycling center or a Treatment, Storage and Disposal Facility (TSDF) to keep you safe and in compliance.

Why Are Damaged Lithium Batteries Dangerous?

Damaged or defective lithium batteries can pose several safety risks, including:

Fire Hazard: Lithium batteries can ignite or explode if punctured, short-circuited, or overheated.

Chemical Risks: If the battery casing is compromised, toxic chemicals may leak (liquid or gas). They contain corrosive electrolytes which can harm skin, lungs, and eyes.

Environmental Concerns: Improper disposal can lead to environmental contamination, in which the toxic materials in the damaged batteries can enter water sources and pollute them. Also, improper incineration can release toxic fumes into the air.

Identifying Damaged Lithium Batteries

To handle lithium batteries safely, it’s crucial to identify any defects. Common indicators include:

- Physical Damage: Look for dents, cracks, or deformation in the battery casing.

- Leakage: Check for any signs of liquid or powder leaking from the battery.

- Excessive Heat: A battery that feels unusually hot is a warning sign.

- Swelling: Bulging or puffing of the battery casing indicates damage.

Safe Handling Practices

When managing damaged or defective lithium batteries, follow these safety guidelines:

- Wear Protective Gear: Always use gloves and safety glasses to guard against potential leaks or chemical exposure.

- Work in a Ventilated Area: Ensure proper ventilation to minimize exposure to toxic fumes.

- Avoid Short-Circuiting: Keep battery terminals away from conductive materials to prevent short circuits and reduce fire risk.

- Limit Movement: Minimize handling to avoid further damage to the battery.

- Use Appropriate Containers: Store damaged batteries in non-conductive, fire-resistant containers, such as specialized lithium battery bags or pails designed for hazardous materials.

Packing and Shipping Damaged Lithium Batteries

Transporting damaged lithium batteries requires strict adherence to the US DOT regulations outlined in 49 CFR 173.185(f) or an applicable US DOT Special Permit (49 CFR 107.105). Here are the key requirements:

- Transport Method: Damaged batteries can only be transported by highway, rail, or vessel. They cannot be transported by air for safety reasons.

- Hazardous Materials Training: US DOT requires employees involved in packing and shipping damaged lithium batteries to receive hazardous materials training.

Packaging Steps

- Inner Packaging: Each cell or battery should be placed in non-metallic inner packaging that fully encloses it. This prevents short circuits and further damage.

- Outer Packaging: The inner package must then be placed into Packing Group I performance-level packaging, filled with cushioning material that is non-conductive, non-combustible, and absorbent. Only one inner package should go into one outer package.

- Labeling: Clearly mark and label the outer package with the required information (e.g., Hazard Class 9 label). The outer package must also indicate that it contains a “damaged/defective lithium ion battery.”

The management of damaged lithium batteries is a critical responsibility for waste generators. While these batteries are essential for powering modern electronics and equipment, their potential hazards cannot be overlooked. By understanding the distinctions between universal and hazardous waste, recognizing the dangers posed by damaged batteries, and adhering to safe handling and transportation practices, companies can protect their employees and the environment. At Elk, our chemists can tackle this challenging task for you. Contact us today to learn how we can help you stay safe and in compliance!

Characteristics of Hazardous Waste

It is important to understand the waste your facility generates. Hazardous waste is heavily regulated, meaning it cannot be discarded with your municipal or residual waste and must be disposed of properly. The Environmental Protection Agency created a two-step process of identifying solid wastes as hazardous wastes under the Resource Conservation Recover Act. The first step is to identify which of the four hazardous waste characteristics is applicable to your solid waste. The next step is to identify the solid waste as a listed waste. It’s interesting to note that a hazardous waste has a hazardous waste characteristic and is a listed waste. Which of the four hazardous waste characteristics applies to your solid waste?

§261.20 General

(a) A solid waste, as defined in §261.2, which is not excluded from regulation as a hazardous waste under §261.4(b), is a hazardous waste if it exhibits any of the characteristics identified in this subpart.

[Comment: §262.11 of this chapter sets forth the generator’s responsibility to determine whether his waste exhibits one or more of the characteristics identified in this subpart]

(b) A hazardous waste which is identified by a characteristic in this subpart is assigned every EPA Hazardous Waste Number that is applicable as set forth in this subpart. This number must be used in complying with the notification requirements of section 3010 of the Act and all applicable recordkeeping and reporting requirements under parts 262 through 265, 268, and 270 of this chapter.

(c) For purposes of this subpart, the Administrator will consider a sample obtained using any of the applicable sampling methods specified in appendix I to be a representative sample within the meaning of part 260 of this chapter.

[Comment: Since the appendix I sampling methods are not being formally adopted by the Administrator, a person who desires to employ an alternative sampling method is not required to demonstrate the equivalency of his method under the procedures set forth in §§260.20 and 260.21.]

[45 FR 33119, May 19, 1980, as amended at 51 FR 40636, Nov. 7, 1986; 55 FR 22684, June 1, 1990; 56 FR 3876, Jan. 31, 1991]

§261.21 Characteristic of Ignitability

(a) A solid waste exhibits the characteristic of ignitability if a representative sample of the waste has any of the following properties:

(1) It is a liquid, other than an aqueous solution containing less than 24 percent alcohol by volume and has flash point less than 60 °C (140 °F), as determined by a Pensky-Martens Closed Cup Tester, using the test method specified in ASTM Standard D 93-79 or D 93-80 (incorporated by reference, see §260.11), or a Setaflash Closed Cup Tester, using the test method specified in ASTM Standard D 3278-78 (incorporated by reference, see §260.11).

(2) It is not a liquid and is capable, under standard temperature and pressure, of causing fire through friction, absorption of moisture or spontaneous chemical changes and, when ignited, burns so vigorously and persistently that it creates a hazard.

(3) It is an ignitable compressed gas. (i) The term “compressed gas” shall designate any material or mixture having in the container an absolute pressure exceeding 40 p.s.i. at 70 °F or, regardless of the pressure at 70 °F, having an absolute pressure exceeding 104 p.s.i. at 130 °F; or any liquid flammable material having a vapor pressure exceeding 40 p.s.i. absolute at 100 °F as determined by ASTM Test D-323. (ii) A compressed gas shall be characterized as ignitable if any one of the following occurs:

(A) Either a mixture of 13 percent or less (by volume) with air forms a flammable mixture or the flammable range with air is wider than 12 percent regardless of the lower limit. These limits shall be determined at atmospheric temperature and pressure. The method of sampling and test procedure shall be acceptable to the Bureau of Explosives and approved by the director, Pipeline and Hazardous Materials Technology, U.S. Department of Transportation (see Note 2).

(B) Using the Bureau of Explosives’ Flame Projection Apparatus (see Note 1), the flame projects more than 18 inches beyond the ignition source with valve opened fully, or, the flame flashes back and burns at the valve with any degree of valve opening.

(C) Using the Bureau of Explosives’ Open Drum Apparatus (see Note 1), there is any significant propagation of flame away from the ignition source.

(D) Using the Bureau of Explosives’ Closed Drum Apparatus (see Note 1), there is any explosion of the vapor-air mixture in the drum.

(4) It is an oxidizer. An oxidizer for the purpose of this subchapter is a substance such as a chlorate, permanganate, inorganic peroxide, or a nitrate, that yields oxygen readily to stimulate the combustion of organic matter (see Note 4). (i) An organic compound containing the bivalent -O-O- structure and which may be considered a derivative of hydrogen peroxide where one or more of the hydrogen atoms have been replaced by organic radicals must be classed as an organic peroxide unless:

(A) The material meets the definition of a Class A explosive or a Class B explosive, as defined in §261.23(a)(8), in which case it must be classed as an explosive,

(B) The material is forbidden to be offered for transportation according to 49 CFR 172.101 and 49 CFR 173.21,

(C) It is determined that the predominant hazard of the material containing an organic peroxide is other than that of an organic peroxide, or

(D) According to data on file with the Pipeline and Hazardous Materials Safety Administration in the U.S. Department of Transportation (see Note 3), it has been determined that the material does not present a hazard in transportation.

(b) A solid waste that exhibits the characteristic of ignitability has the EPA Hazardous Waste Number of D001.

Note 1: A description of the Bureau of Explosives’ Flame Projection Apparatus, Open Drum Apparatus, Closed Drum Apparatus, and method of tests may be procured from the Bureau of Explosives.

Note 2: As part of a U.S. Department of Transportation (DOT) reorganization, the Office of Hazardous Materials Technology (OHMT), which was the office listed in the 1980 publication of 49 CFR 173.300 for the purposes of approving sampling and test procedures for a flammable gas, ceased operations on February 20, 2005. OHMT programs have moved to the Pipeline and Hazardous Materials Safety Administration (PHMSA) in the DOT.

Note 3: As part of a U.S. Department of Transportation (DOT) reorganization, the Research and Special Programs Administration (RSPA), which was the office listed in the 1980 publication of 49 CFR 173.151a for the purposes of determining that a material does not present a hazard in transport, ceased operations on February 20, 2005. RSPA programs have moved to the Pipeline and Hazardous Materials Safety Administration (PHMSA) in the DOT.

Note 4: The DOT regulatory definition of an oxidizer was contained in §173.151 of 49 CFR, and the definition of an organic peroxide was contained in paragraph 173.151a. An organic peroxide is a type of oxidizer.

[45 FR 33119, May 19, 1980, as amended at 46 FR 35247, July 7, 1981; 55 FR 22684, June 1, 1990; 70 FR 34561, June 14, 2005; 71 FR 40259, July 14, 2006]

§261.22 Characteristic of Corrosivity

(a) A solid waste exhibits the characteristic of corrosivity if a representative sample of the waste has either of the following properties:

(1) It is aqueous and has a pH less than or equal to 2 or greater than or equal to 12.5, as determined by a pH meter using Method 9040C in “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods,” EPA Publication SW-846, as incorporated by reference in §260.11 of this chapter.

(2) It is a liquid and corrodes steel (SAE 1020) at a rate greater than 6.35 mm (0.250 inch) per year at a test temperature of 55 °C (130 °F) as determined by Method 1110A in “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods,” EPA Publication SW-846, and as incorporated by reference in §260.11 of this chapter.

(b) A solid waste that exhibits the characteristic of corrosivity has the EPA Hazardous Waste Number of D002.

[45 FR 33119, May 19, 1980, as amended at 46 FR 35247, July 7, 1981; 55 FR 22684, June 1, 1990; 58 FR 46049, Aug. 31, 1993; 70 FR 34561, June 14, 2005]

§261.23 Characteristic of Reactivity

(a) A solid waste exhibits the characteristic of reactivity if a representative sample of the waste has any of the following properties:

(1) It is normally unstable and readily undergoes violent change without detonating.

(2) It reacts violently with water.

(3) It forms potentially explosive mixtures with water.

(4) When mixed with water, it generates toxic gases, vapors or fumes in a quantity sufficient to present a danger to human health or the environment.

(5) It is a cyanide or sulfide bearing waste which, when exposed to pH conditions between 2 and 12.5, can generate toxic gases, vapors or fumes in a quantity sufficient to present a danger to human health or the environment.

(6) It is capable of detonation or explosive reaction if it is subjected to a strong initiating source or if heated under confinement.

(7) It is readily capable of detonation or explosive decomposition or reaction at standard temperature and pressure.

(8) It is a forbidden explosive as defined in 49 CFR 173.54, or is a Division 1.1, 1.2 or 1.3 explosive as defined in 49 CFR 173.50 and 173.53.

(b) A solid waste that exhibits the characteristic of reactivity has the EPA Hazardous Waste Number of D003.

[45 FR 33119, May 19, 1980, as amended at 55 FR 22684, June 1, 1990; 75 FR 13002, Mar. 18, 2010]

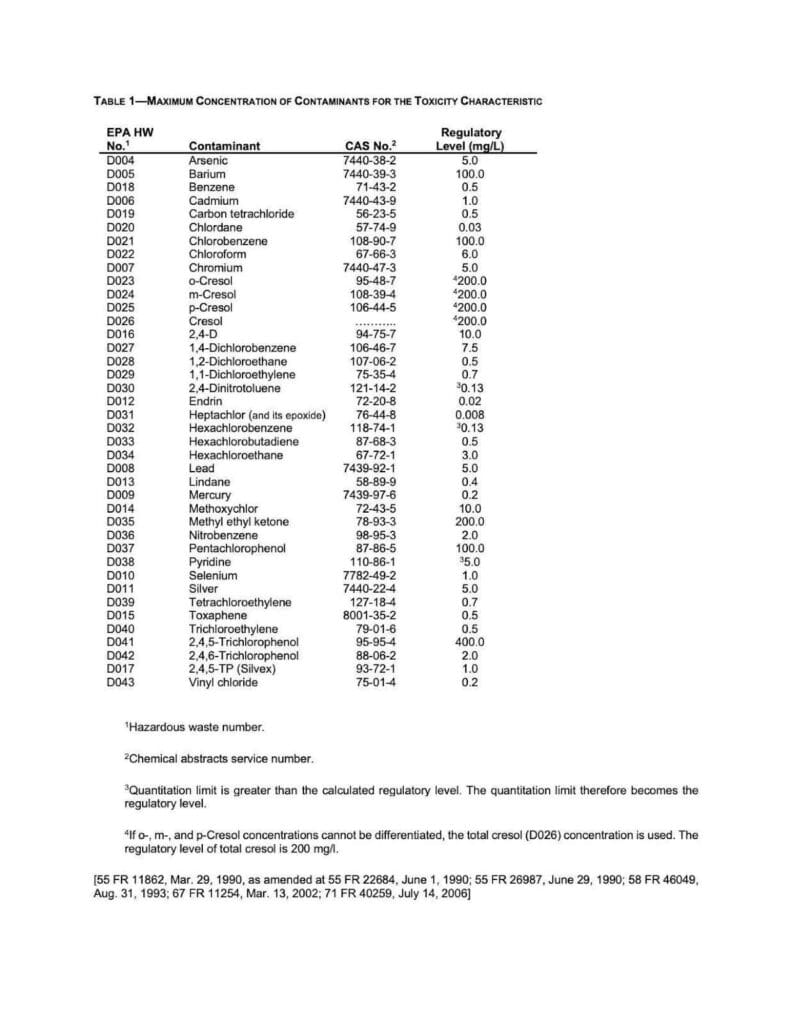

§261.24 Toxicity Characteristic

(a) A solid waste (except manufactured gas plant waste) exhibits the characteristic of toxicity if, using the Toxicity Characteristic Leaching Procedure, test Method 1311 in “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods,” EPA Publication SW-846, as incorporated by reference in §260.11 of this chapter, the extract from a representative sample of the waste contains any of the contaminants listed in table 1 at the concentration equal to or greater than the respective value given in that table. Where the waste contains less than 0.5 percent filterable solids, the waste itself, after filtering using the methodology outlined in Method 1311, is considered to be the extract for the purpose of this section.

(b) A solid waste that exhibits the characteristic of toxicity has the EPA Hazardous Waste Number specified in Table 1 which corresponds to the toxic contaminant causing it to be hazardous.

PA DEP Requirements for Labeling

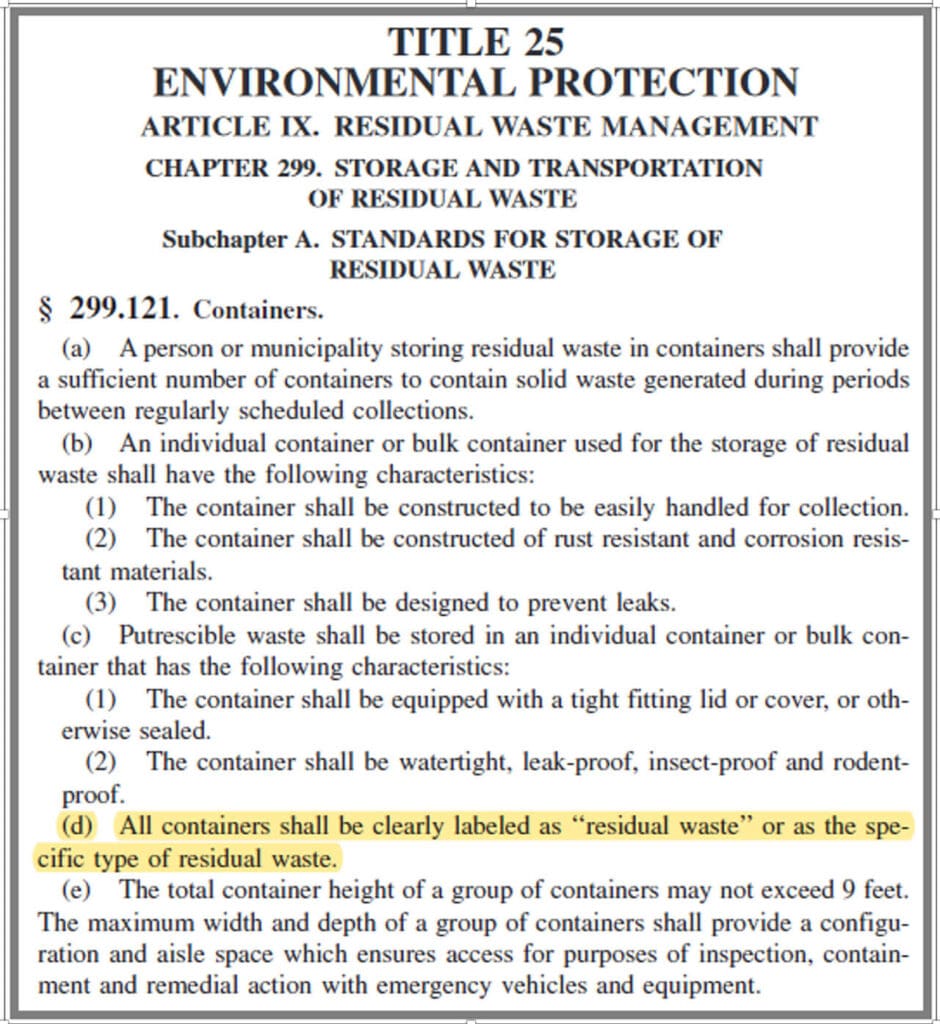

Containers of Residual Waste

Pursuant to 25 Pa. Code 299.121(d), All containers storing residual waste shall be clearly labeled as ‘‘Residual Waste’’ or as the specific type of residual waste.

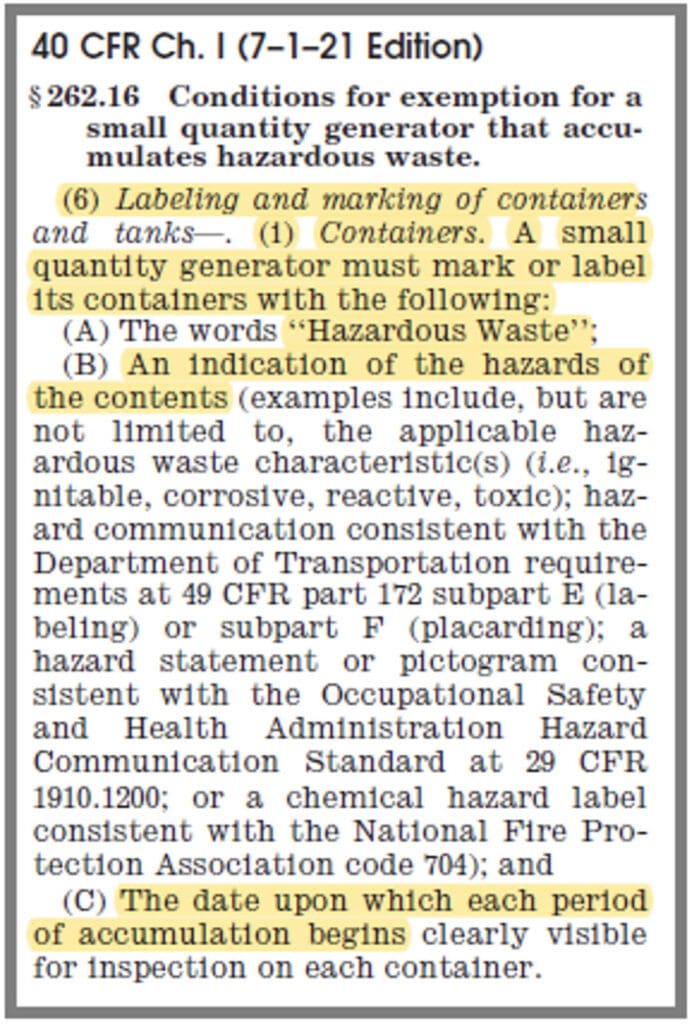

EPA Requirements for SQG Labeling

Containers of Hazardous Waste

A small quantity generator may accumulate hazardous waste on site without a permit or interim status, and without complying with the requirements of parts 124, 264 through 267, and 270 of this chapter, or the notification requirements of section 3010 of RCRA, provided that all the conditions for exemption listed in 40 CFR 262.16 are met:

Pursuant to 40 CFR 262.16(b)(2)(iii)(A), A container holding hazardous waste must always be closed during accumulation, except when it is necessary to add or remove waste.

Pursuant to 40 CFR 262.16(b)(6), A Small Quantity Generator must mark or label its containers with the following:

(A) The words “Hazardous Waste”;

(B) An indication of the hazards of the contents;

(C) The date upon which each period of accumulation begins clearly visible for inspection on each container.

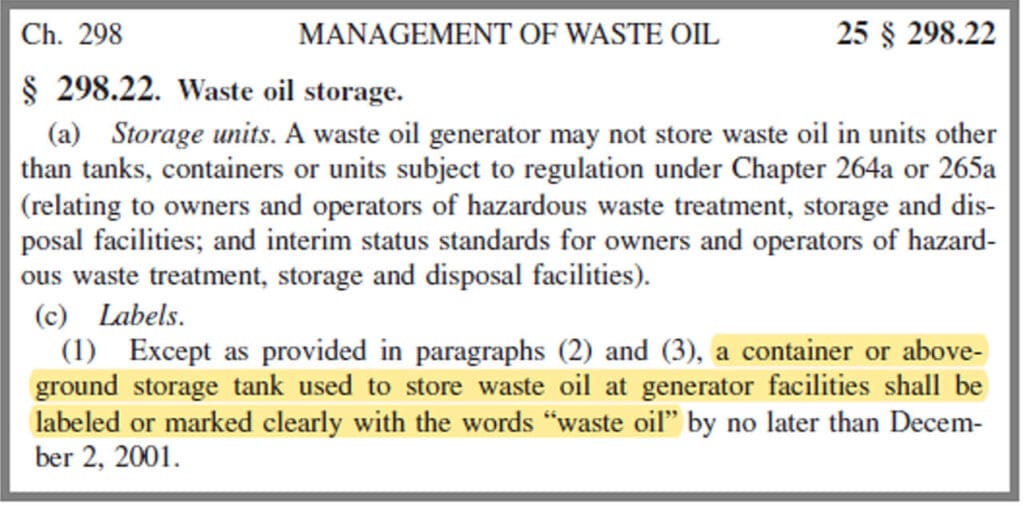

PA DEP Requirements for

Labeling Containers of Waste Oil

Pursuant to 25 Pa. Code 298.20(a), 25 Pa. Code Subchapter C (WASTE OIL GENERATORS) applies to a waste oil generator. A waste oil generator is a person, by site, whose act or process produces waste oil or whose act first causes waste oil to become subject to regulation.

25 Pa. Code 298.22 – Waste oil storage.

(a) Storage units. A waste oil generator may not store waste oil in units other than tanks, containers or units subject to regulation under Chapter 264a or 265a (relating to owners and operators of hazardous waste treatment, storage and disposal facilities; and interim status standards for owners and operators of hazardous waste treatment, storage and disposal facilities).

(b) Condition of units. A container or above ground storage tank used to store waste oil at generator facilities shall meet the following requirements:

(1) Be in good condition. For example, containers and above ground storage tanks may not exhibit severe rusting, apparent structural defects or deterioration.

(2) Not leaking (no visible leaks).

Pursuant to 25 Pa. Code 298.22(c)(1), a container or above ground storage tank used to store waste oil at generator facilities shall be labeled or marked clearly with the words:“Waste Oil”.

Browse resources and industry information from Elk Environmental.

Regulatory Updates

We stay up to date on the latest regulatory updates to help us provide the best solutions for your environmental needs.

Articles

Affiliated Companies with The Empire Group